Tiger Xl Heavyweight Workshop Shed – Show Site Review

First Added - November 28 2025

Last Updated - November 28 2025 - 0 Data Points Updated - 0 Data Points Added

Reviewed & curated by a panel of garden building experts. Using methodology 1.1

Product ID: tiger-sheds-tiger-xl-heavyweight-workshop-shed

Size: Multiple sizes available

Merchants Checked: 10

Available From: 1

Support WhatShed: by making a purchase after clicking a link above, a portion of the sale supports this site.

There are sheds… and then there are big sheds.

And once you move into genuinely large wooden buildings, the rules change.

The Tiger XL Heavyweight Workshop sits right at that tipping point — the point where size stops being cosmetic and starts becoming structural. This is the largest 12mm shiplap tongue-and-groove workshop Tiger make, and we inspected it in person at the Otley show site, in the 20x10ft configuration, which is the biggest footprint available.

That matters, because big equals complex.

It is always harder to manufacture a large timber building than a small one. Not marginally harder — exponentially harder. Long wall runs magnify alignment errors. Roof spans expose weak joins. Floors reveal bearer spacing mistakes immediately. And if a manufacturer lacks structural discipline, it’s on the biggest buildings that things start to go wrong.

I’ve seen it happen.

Years ago, I used to drive past a long modular workshop erected as part of a farm shop. Similar footprint. Similar intent. Bought cheaply. And you could tell — even from the road — that it wasn’t right. The walls had a subtle waviness, like a Swiss roll or a chocolate log: not collapsing, but never truly straight. OSB roof. Cheap joins. Cost-led decisions.

Within a year, it was gone.

Pulled down.

So when I walked up to the Tiger XL Heavyweight Workshop, my first instinct wasn’t excitement — it was scrutiny. I wanted to see if it suffered from the same weaknesses I’ve seen in other large or pseudo-modular timber buildings.

It doesn’t.

First impressions: scale, confidence, and finish

From the outside, the first thing you notice is scale — but the second thing you notice is control.

This doesn’t look like a big shed that’s been pushed to its limits. It looks like a big shed that’s been designed to be big.

The 12mm finish shiplap tongue-and-groove cladding is beautifully milled — smooth enough that you instinctively want to run your hand along it. No roughness. No splintery edges. No sense that the boards are thin or stressed. It has that quiet confidence you only get when timber is properly selected and properly finished.

And importantly, the long wall runs are straight. No waviness. No bowing. No optical distortions that make you question what will happen after the first winter.

That alone puts this workshop in a different league to many large sheds on the market.

Doors, access, and the reality of valuables

The double doors are big — properly big — and give excellent access for larger equipment. Ride-on mowers, motorcycles, workbenches, sheet materials — all realistic use cases here.

Tiger specify the doors as fully boarded tongue-and-groove double doors, measuring 1132mm x 1800mm, with a lock and key as standard . In practice, they feel exactly as they should: substantial, well-braced, and square in the frame.

That said, I’ll flag something important — not as a criticism, but as an experienced user’s note.

The external hinges are screw-fixed. On a building of this size, where it’s very likely you’ll store valuable kit, that’s one area I would personally upgrade. Coach bolts or security hinges would remove a potential weak point. It’s not a flaw in construction — it’s just a sensible hardening step for a workshop of this scale.

Stepping inside: space, light, and structural intent

Once the doors open, the internal impression is immediate and frankly impressive.

The best way I can describe it is cathedral-like — not in height alone, but in openness. The apex roof, combined with the sheer width and length of the building, creates a sense of air and possibility.

This isn’t a glorified storage box. This is a workspace.

Running down the centre of the roof is a central A-frame, positioned halfway along the building. This is a critical structural feature — and it’s been done properly. It doesn’t feel intrusive. It doesn’t eat into usable space. Instead, it quietly ties the two halves of the building together and locks the roof structure as a single unit.

This is where Tiger’s experience shows. Lesser manufacturers avoid features like this because they cost money and require precision. Here, it’s clearly been designed in from the outset.

Windows and internal environment

The XL comes with a full bank of windows — ten on the 20×10 model — all glazed with 3mm toughened glass . The result is one of the brightest workshops we’ve reviewed.

Light floods the space.

This matters far more than people realise. Natural light changes how you use a building. It reduces fatigue. It makes work feel less enclosed. And it allows you to work safely without relying on artificial lighting during the day.

Despite the extensive glazing, the structure never felt compromised — which is exactly what you want in a potently glazed workshop. This is where cheaper builds often start to feel flimsy. Not here.

Floor strength: measured, not guessed

Big sheds live or die by their floors.

Tiger use 12mm tongue-and-groove flooring, supported by consistent bearer spacing across the entire XL range. Crucially, they haven’t widened bearer gaps to save money as footprint increases — a common and disastrous shortcut.

We tested this properly.

Using a 75kg load, placed at multiple points across the floor, and measured with a laser range finder, we recorded an average deflection of just 2mm.

That’s exceptional — especially at this scale.

Underfoot, the floor feels exactly as the numbers suggest: firm, taut, confidence-inspiring. No bounce. No flex. No hollow drumming. Just solid timber doing what solid timber should do.

Wall rigidity and frame performance

We carried out the same 75kg load test against the rear wall — one of the longest uninterrupted wall runs on the building.

Measured movement: approximately 4mm.

That’s with the standard 28mm x 44mm framing .

In other words: already very good.

If you opt for Tiger’s heavy-duty framing upgrade, which effectively doubles frame thickness, this building moves firmly into over-engineered territory — the sort of rigidity you simply don’t see in mass-market workshops.

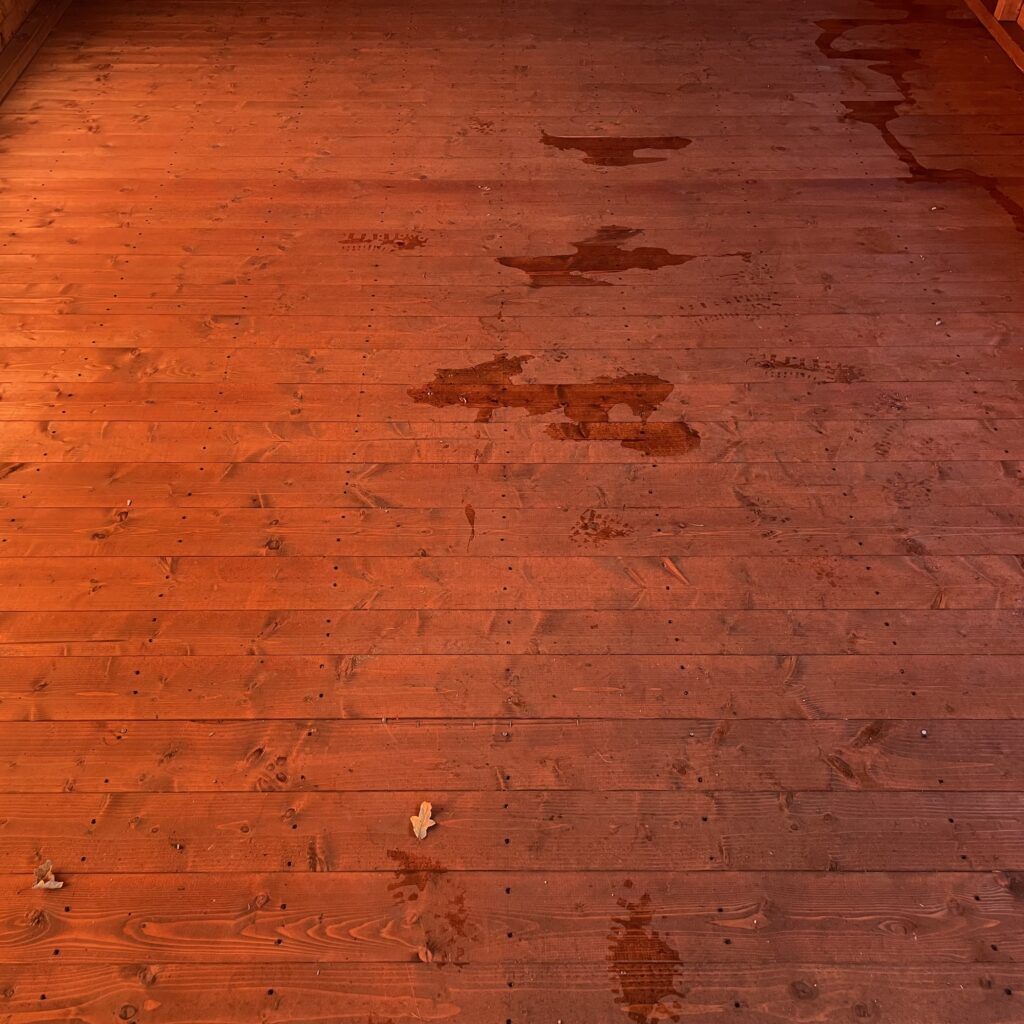

Roof construction and weather performance

The roof is built from 12mm tongue-and-groove boards, finished with black mineral felt .

Mineral felt matters. We’ve seen cheap felt tear, lift, and degrade within a year on large buildings. Mineral felt is thicker, tougher, and far more resistant to movement and weather stress.

This particular building had been erected for around 12 months, and we inspected it the day after a storm.

Inside conditions:

- No water ingress

- No staining

- No damp smell

- No drafts

We also took moisture readings, which averaged around 14% internally — exactly where you want a well-ventilated timber building to sit. Dry, but not artificially desiccated. Healthy.

Joins, alignment, and the modular question

One of my biggest concerns going in was whether this would feel like two workshops bolted together.

It doesn’t.

The internal joins are beautifully aligned, reinforced with substantial framing, and visually seamless. There are no gaps. No stress points. No sense of compromise. The roof ties, floor bearers, and wall framing all interlock as a single system.

This is not a “cut and shut” building. It’s a coherent structure.

Height, airiness, and usability

I’m six foot tall, and I couldn’t touch the apex at full stretch.

That matters.

It means the space doesn’t just store things — it accommodates people. Movement is easy. Air circulates properly. Heat doesn’t feel trapped at head height. And psychologically, it feels like a place you can work in for hours without fatigue.

This is where the XL genuinely separates itself from smaller workshops.

Upgrade paths that actually make sense

Two upgrades are worth serious consideration here:

- Heavy-duty framing — if you want maximum rigidity, longevity, or you’re in an exposed location.

- Loglap cladding — which adds both visual mass and additional weather resilience.

Neither is required — the standard build is already excellent — but both push the building into truly premium territory.

Final verdict: a large shed done properly

The Tiger XL Heavyweight Workshop is one of the most impressive large timber buildings we’ve reviewed — not because it’s flashy, but because it’s disciplined.

It’s straight. It’s solid. It’s dry. It’s bright. And it’s structurally honest.

This is what happens when a manufacturer understands that big sheds magnify mistakes — and designs accordingly.

If you want a genuinely large workshop that doesn’t feel compromised, doesn’t rely on OSB shortcuts, and doesn’t leave you worrying about what the first winter will bring, this is an outstanding option.

Put it on a proper base. Treat it properly. And there’s no reason this shouldn’t still be standing — straight, dry, and usable — many years down the line.

That’s the highest compliment I can give a shed of this size.